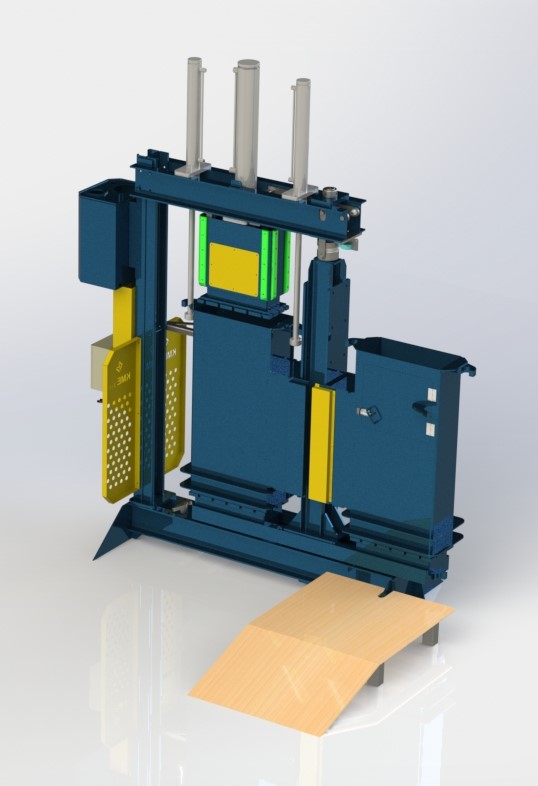

EasyBale Bale Press

Our customer has had to delay their order. Therefore KME Ltd...

EasyBale Bale Press

Our customer has had to delay their order. Therefore KME Ltd...

The KME grass block press has been designed to produce 1kg blocks of grass approx. 150mm...

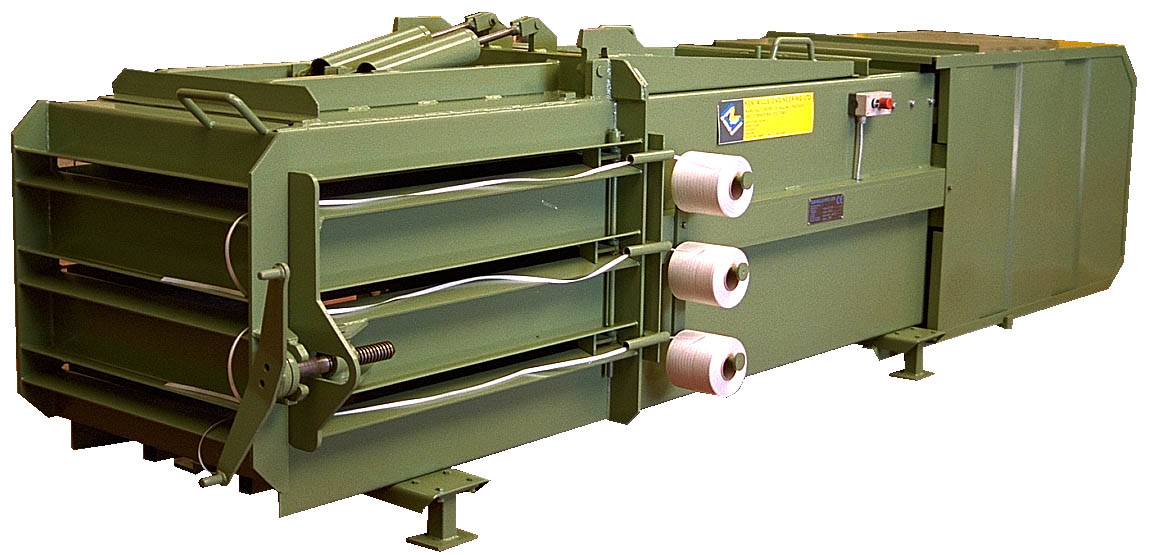

T200 Revolver Bale press is designed for the high production of textile materials into...

60 Revolver Bale press is designed for the high production of textile materials into...

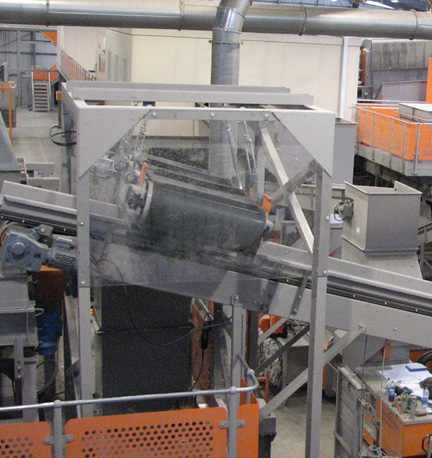

Take a look at the unique KME textile bale breaking system, the perfect piece of machinery...

The Aries twin ram baler is our fully automatic baler range that suits a high production...

KME Ltds industry leading machinery for rebaling large round or square bales of haylage....

The T40 Semi Automatic Horizontal Baler is one of our smaller models of balers for dealing...

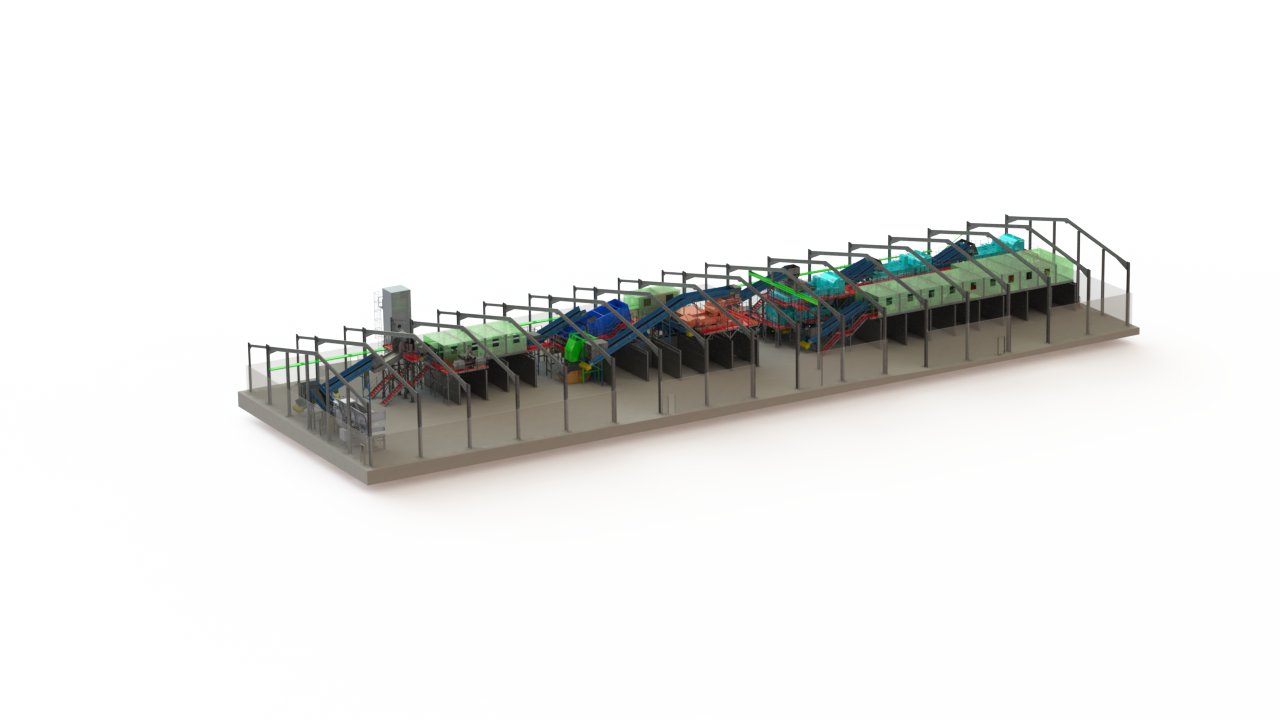

KME Ltd have over 40 years industry experience designing Material Recycling Facilities...

FOR SALE – used bagging press, good condition has been used for bagging chopped straw...

The Accerator screen is design to feed NIR optical sorting equipment to help remove small...

The CP Glass Trommel is a revolving cylinder screen that separates mixed glass particles...

Aluminum is passed over the rotor which contains a rotating series of powerful rare earth...

MSS, a division of the CP Group, is leading the industry in state-of-the-art optical...

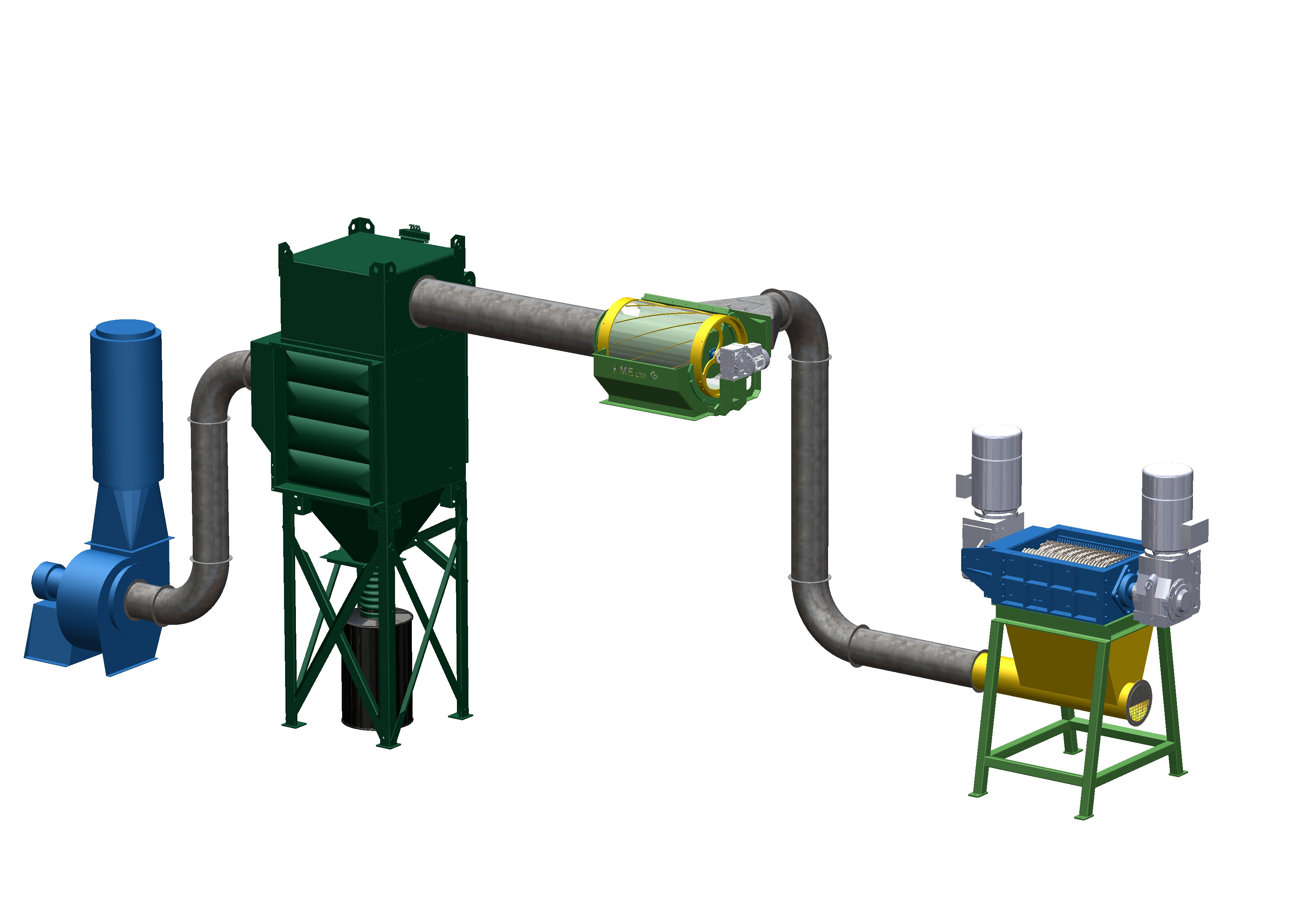

Generate highly absorbant low dust animal bedding form clean uncontaminated cardboard,...

As a manufacture we can make any size of industrial shredder to suit your needs and fit...

KME Ltd design and manufacture a wide range of waste conveyors suited to different...

Foam Baling machine for the compaction of foam into high density bales suitable for export...

Semi-automatic horizontal baler with 70 tonnes of pressure for the processing of many...

.jpg)

Semi automatic horizontal baler with 50 tonnes of pressure for the processing of many...

A small compact Horizontal bale press ideally suited in a warehouse / small distribution...

The UBC Auto Bale Press is designed for continuous, automatic baling of steel and...

Our range of twin ram fully automatic balers can be modified for baling RDF and SRF...

The bale breaker is designed to break up large bales of haylage, straw and hay. Large...

The perfect system for any serious forage or bedding producer, KME are the market leaders...

The Delivery drum is a high efficiency pneumatic conveying and dust extraction unit that...

The KME shavings baler is designed to work as a stand alone bagging press to bag up your...

A disc screen system for the breaking and removal of small fraction and glass from a mixed...

CP’s Newscreen consists of (3) decks: top deck with steel discs, bottom deck with steel...

The OCC screen automatically separate large OCC from other fibres and containers. The...

The most advanced container/paper separation in the industry! The patented V-Screen...

Optical Sorting of Plastics by Resin Type and Color.

The Aladdin™ sorts plastic...

KME offers an over-belt Electro Magnetic Separator that allows for quick and efficient...

Trommel Screen that delivers high-throughput paired with high-quality end-products....

Our wiper bagging presses are the ideal product for baling up your wiping rags, it can be...

Designed for the high production of textile fibre & material into low / medium density...

Are you baling 2nd hand clothing for export? This is the machine for the job, high...

KME Ltd’s unique one touch sorting system for the separation of clothing direct off...

T200 Single box Bale press is designed for the low production of textile materials into...

60 Revolver Bale press is designed for the high production of textile materials into...

The Mutilating machine has been designed with a completely unique cutting/feed system to...

The perfect machine for baling wiping rags, available in 6 different pack weights - 2, 5,...

KME are proud of the fact that everything that we design we manufacture in house at our UK...

Our Form Fill & Seal systems form bags from a roll of film, which is then filled with...

KME pride themselves on the quality build of every machine that leaves our factory. Our...