Our Services

Everything in one place making your buying process easy

At KME Ltd we pride ourselves on being a UK manufacturer with the ability to provide the best possible buying experience for our clients. Everything is designed and manufactured in house in our UK premises housing some of the best equipment on the market. Our design team have more than 50 years industry knowledge allowing them to create bespoke systems to suit your location, processing requirements and allow you to improve your operations and meet your recycling targets.

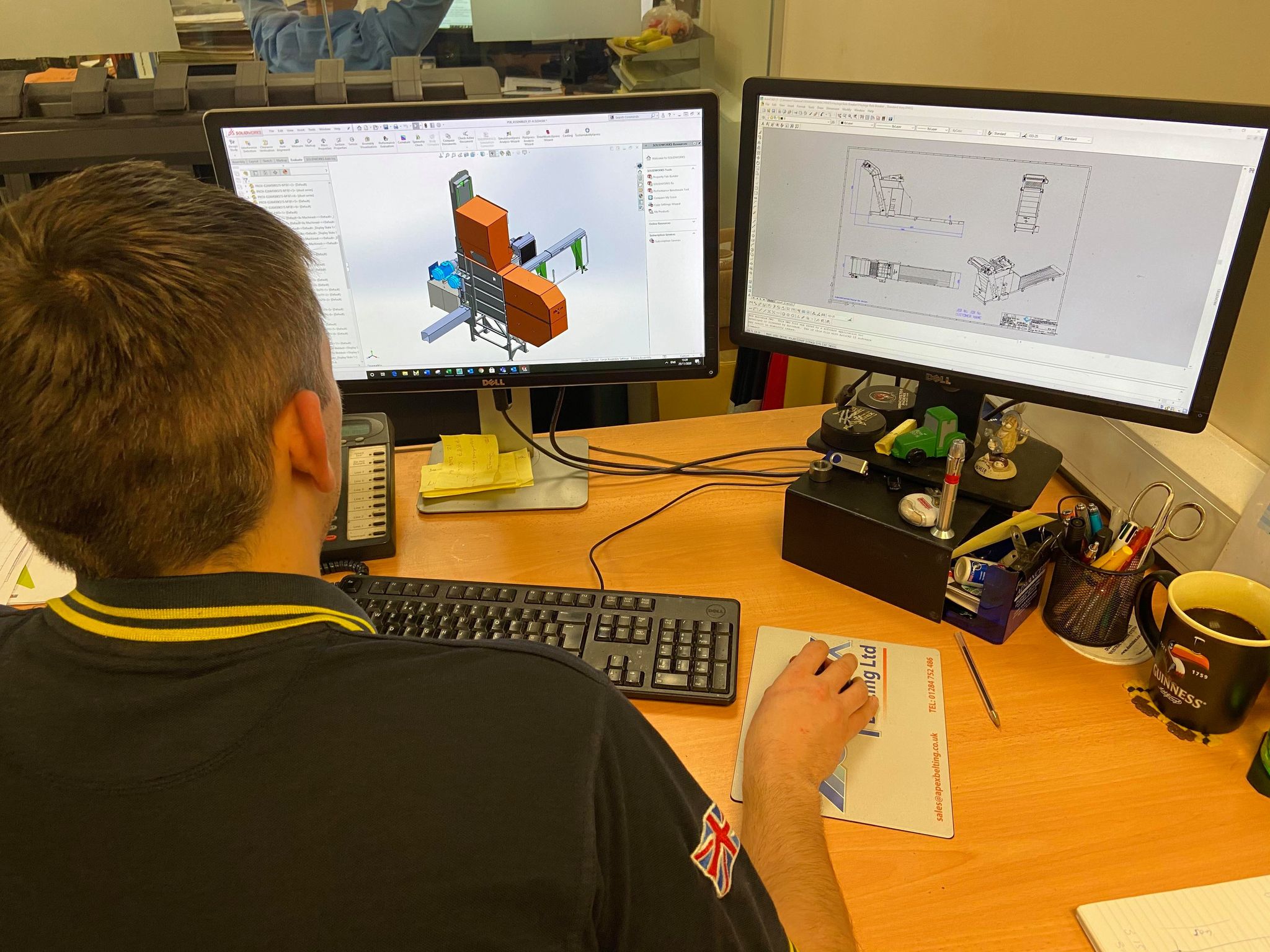

1 In House Design

A team of design engineers ready to bring your plans to life.

From concept design, through to full system & final manufacturing design and purchasing the whole process is carried out in house under the supervision of experienced long serving staff with over 50 years experience in the business. KME use the latest in 3D designing. Upon completion of the design these drawings are issued within the same premises to the production manager who overseas the manufacture of the item / machinery. Where applicable the machinery would be tested in house before delivery and installation to the customer.

2 Fabrication

Metal fabrication creating your metal structures by cutting, bending and assembling

After design and procurement the main raw material are ordered and when delivered the steel is cut and the profiles / components are fabricated to create the components of the system which includes the baling machine structure, support platforms and frames, support legs for the platforms and conveyors etc. Once complete they go on for fitting / painting.

3 Machine Shop

Specialist department within our warehouse using top of the range machinery

The items required for the installation which need machining are processed though the machines shop. The processes required will depend on the item and would typically require the following machinery CNC lathe, CNC machining centre, Manual lathe, manual milling machine, surface grinder etc. The items that are typically processes are the conveyor rollers, hydraulic cylinders, chain drive, conveyor carrier rollers, tying device for baling machinery etc.

4 Laser Cutting

Operating the ‘Best in Class’ high definition cutting system

Our Bystronic BySmart Fibre laser offers high-speed precision cutting and enhanced cut quality. Its ability to efficiently handle a diverse range of material thicknesses makes it a versatile tool for various applications. Moreover, it boosts production rates, which is essential for increasing productivity without compromising the quality of our output, making it a valuable asset for our business for optimising our manufacturing process.

5 Hydraulic Systems

Our Hydraulic team are on site and design for each project .

The hydraulic systems required for the baling equipment, walking floors etc. are designed in house and manufactured to suit the requirements of the machinery. The pressure and speed of the system required determines the design and size of each system and typically ranges from small systems with a drive size of 0.55kw up to 45kw for the larger baling machinery.

6 Sheet Metal Department

The Sheet Metal Working department employs fully skilled staff allowing us to create precision work of a consistently high quality

The sheet metal components required for the installation including guards, hoppers, chutes etc. are manufactured in house using some of the following equipment – CNC guillotine, hydraulic folding unit, spot welding unit, rollers, benders etc. The delivery / timescales and quality can be controlled to ensure a high quality end produce on time.

7 Electrical Design & Manufacture

Fully qualified electrical engineers wire up your machinery

The electrical control systems are designed, Manufactured and fitted to the machinery all as an in house process. Once fitted / installed on the machine the system is tested for operation and safety prior to delivery to the client. The same electrical engineers who have built the systems would attend site to oversee the installation and commissioning.

8 Fitting & Final Testing

Making sure everything is perfect before delivery

Once all the components required have been made from the above operation they are finally assembled including the hydraulics and electrical components. Once finished and painted they are tested prior to delivery and installation.

9 Service & Installation

Rest assured that installation is done by the same engineers that built your machinery not outsourced to another firm

The Installation of the system is carried out by our own experienced staff which makes for an efficient safe install. The quality from the design through manufacture is also passed through the installation stage to ensure a high quality system on time and on budget.